Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Blog Article

Just How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser right into Fibre production procedures represents a significant innovation in quality control methods. By supplying real-time, exact dimensions of Fibre diameters, this technology attends to the crucial requirement for uniformity in manufacturing criteria.

Importance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is essential in the area of optical Fibre technology, as it directly influences the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, attenuation, and overall transmission performance. Precision in measuring Fibre Diameter guarantees that the optical buildings are maintained within defined resistances, which is important for optimal signal honesty.

Variants in Fibre Diameter can result in increased losses due to spreading and modal diffusion, impacting the quality of information transmission. In high-speed communication systems, such disparities can cause considerable destruction of signal quality, bring about information errors and lowered efficiency. Regular Fibre Diameter is essential for compatibility with connectors and splicing innovations, which are important components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily depend on precise Diameter measurements to make sure conformity with sector requirements. By carrying out durable dimension strategies, suppliers can enhance item dependability, lessen waste, and boost general system efficiency. Thus, the importance of Fibre Diameter dimension can not be overemphasized, as it acts as a keystone in the innovation of optical Fibre innovation and its applications in contemporary communication networks.

Exactly How the Analyser Works

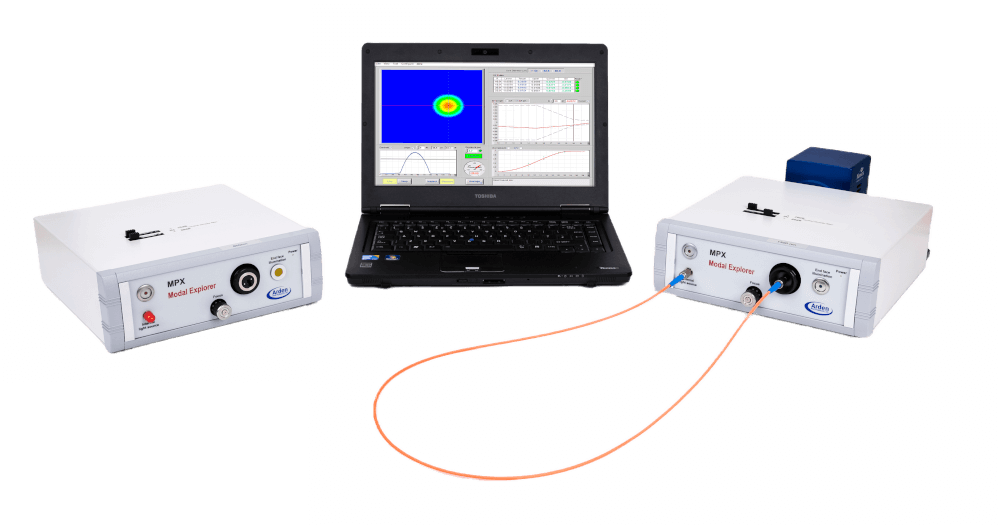

The reliable measurement of Fibre Diameter depends on advanced logical strategies that make sure accuracy and dependability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced picture processing formulas to accurately analyze the Diameter of fibers as they are generated

At first, a laser light beam is guided at the moving Fibre, creating a cross-sectional shadow. The analyser captures this shadow using high-resolution cams positioned purposefully along the assembly line. The recorded pictures are then processed in real-time to figure out the Fibre's Diameter with remarkable accuracy.

The system uses sophisticated formulas that represent numerous elements, consisting of variations in light intensity and environmental conditions, to improve measurement dependability. It can identify minute adjustments in Diameter, such as variations that could take place throughout the production procedure.

Furthermore, the analyser is capable of taking care of several fibres simultaneously, boosting throughput without compromising precision. By supplying rapid responses on the Diameter, the Optical Fibre Diameter Analyser plays an important role in preserving stringent quality control standards, making sure that the end product fulfills market specs and customer requirements.

Benefits of Real-Time Surveillance

While conventional approaches of checking Fibre Diameter usually include taxing post-production checks, real-time surveillance considerably boosts the efficiency and high quality of optical Fibre production. optical fibre diameter analyser. This proactive technique permits manufacturers to recognize inconsistencies in Fibre Diameter as they happen, instead than waiting till production is full to evaluate top quality

By constantly gauging the Diameter during manufacturing, makers can guarantee that the fibers fulfill strict requirements, resulting in minimized variability and boosted consistency. Real-time tracking likewise enables immediate rehabilitative actions to be taken, decreasing waste and preventing malfunctioning fibers from going into the supply chain.

In addition, this technology facilitates enhanced information collection and evaluation, supplying understandings right into manufacturing fads and possible areas for renovation. Such data-driven decision-making equips makers to optimize procedures and keep high criteria of quality assurance.

Additionally, real-time monitoring promotes a society of continuous renovation within the manufacturing environment. Employees are more involved when they can see the impact of their work in real-time, causing enhanced liability and a commitment to quality. Generally, the implementation of real-time tracking systems in optical Fibre manufacturing translates to premium product high quality and raised consumer satisfaction.

Influence On Production Performance

Applying optical Fibre Diameter analysers substantially boosts production efficiency by streamlining the manufacturing procedure. These tools promote constant surveillance of Fibre Diameter, enabling manufacturers to discover deviations in real-time. By determining incongruities without delay, assembly line can be adjusted rapidly, reducing downtime and reducing the chance of generating defective items.

Additionally, navigate here the combination of these analysers right into the manufacturing operations allows better resource appropriation. With precise Diameter dimensions, operators can optimize product use, making certain that sources are not wasted on mistaken fibres. This precision also contributes to less junk and remodel, ultimately lowering manufacturing expenses.

The automation offered by optical Fibre Diameter analysers decreases reliance on hand-operated evaluations, which are commonly time-consuming and susceptible to human error. Because of this, workers can concentrate on more calculated tasks, boosting overall efficiency.

Furthermore, the information produced from these analysers can inform procedure renovations and promote much better decision-making. By assessing patterns in Fibre Diameter variants, makers can apply aggressive procedures to boost production strategies and preserve constant quality. In summary, optical Fibre Diameter analysers play a crucial function in boosting production efficiency, leading to greater high quality outcome and boosted productivity.

Situation Researches and Success Stories

Throughout numerous sectors, instance researches highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One prominent example is a leading telecommunications firm that faced challenges with inconsistent Fibre diameters, bring about increased being rejected prices. By integrating an optical Fibre Diameter analyser, the company accomplished real-time surveillance of Fibre dimensions, causing a 30% decrease in flaws and substantial expense financial savings.

Moreover, a research organization concentrating on advanced materials made use of optical Fibre Diameter analysers to improve their experimental processes. The analyser's capacity to supply in-depth insights right into Fibre consistency made it possible for the advancement of innovative products with improved performance characteristics.

These success tales highlight the important function of optical Fibre Diameter analysers in improving quality assurance, improving manufacturing performance, and driving development across diverse industries.

Conclusion

To conclude, the Optical Fibre Diameter Analyser plays a crucial function in enhancing quality assurance within Fibre production. By giving precise, real-time measurements and helping with instant rehabilitative activities, this technology considerably lowers variability and minimizes waste. The implementation of such advanced tools cultivates a culture of continual renovation and functional efficiency, eventually making certain compliance with market criteria and maintaining competition. As shown via numerous study, the analyser confirms necessary for achieving superior item quality in Fibre production.

The implementation of optical Fibre Diameter analysers permitted for strict quality control, making certain that the produced fibres fulfilled exacting market requirements.In final thought, the Optical Fibre Diameter Analyser plays a pivotal function in improving high quality control within Fibre manufacturing.

Report this page